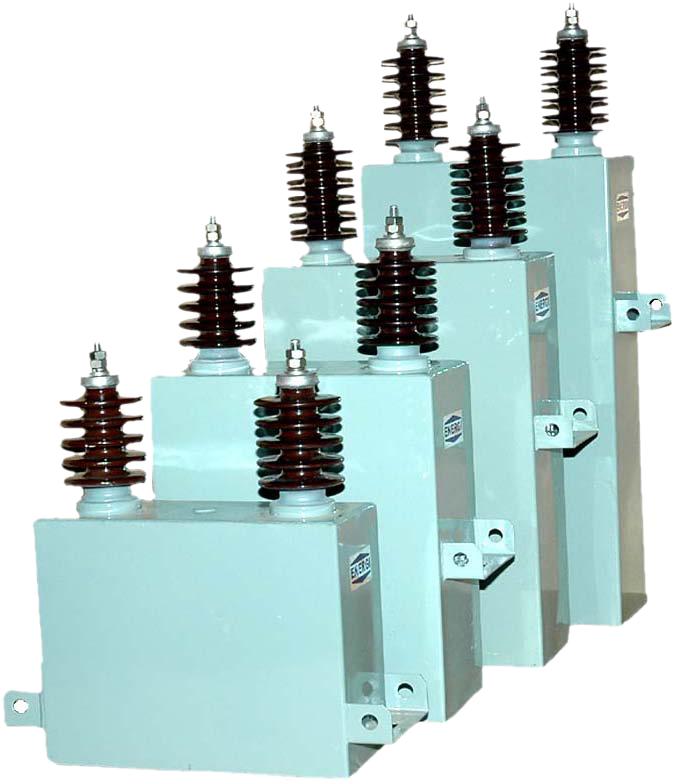

| Make and type |

ENERGE make, Outdoor/ Indoor type |

| Reference Standard |

IS : 13925-1998 with its latest amendments, IEC |

| Rated Capacitor unit |

Upto 1000 KVar |

| Normal System Voltage |

1.1, 3.3, 6.6, 11, 22, 33, 66, 110KV |

| Rated Frequency |

50 Hz |

| Rated current of each capacitor unit |

As per requirement |

| No. of phases |

1 or 3 phase |

| No. of terminals in each unit |

2 or 3 terminals |

| No. of bushings |

Two or Three |

| Type of Bushing Terminals |

Porcelain |

| Connection of capacitor units |

Series-Parallel connections of capacitor unit/phase |

| Maximum permissible over voltage |

110% of rated voltage |

| Maximum permissible current |

130% of rated current |

| Residual voltage |

50 volts or less within 5 minutes. |

| Discharge time |

Less than 5 minutes |

Maximum time interval required

between de-energisation and

re-energisation of the bank |

5 minutes |

Limiting ambient temperature

Voltage withstand test (Capacitor units) |

50 degree C as per IS |

| Teminal to terminal, 10 Secs |

4.3 times rated Dc voltage |

| Terminal to case 50 c/s, 1min |

As per IS |

| Impulse withstand voltage |

As per IS |

| Type of container |

Hermetically sealed, material CRCA |

| Thickness of container |

16 or 14 SWG |

| Details of discharge device |

Internally fitted discharge resistors |

| Surface treatment & painting |

Light phosphating + Prime coating +epoxy grey paint finish

(Special coats and shades on request) |

Generating reactive power at the point of consumption helps energy production and

thus saves energy. It frees power plant capacity for the production of active power and

reduces losses in transmission and distribution systems. At the same time, there is a

higher capacity available for the transmission of active power.

Generating reactive power at the point of consumption helps energy production and

thus saves energy. It frees power plant capacity for the production of active power and

reduces losses in transmission and distribution systems. At the same time, there is a

higher capacity available for the transmission of active power.